Wait a second, what? Yup that’s right, life is too short, too short to spend hours upon hours grinding and hacking and getting pretty much nowhere when somewhere in this fine world is the right tool to get the job done. 15 minutes on te internet, 15 minute diversion on the way to Akupara, 1 hour of work and the rotten ole bulkhead was finally history.

I guess I should back up a bit here and fill in some of the missing details. When we bought Akupara I had a strong suspicion that the anchor locker bulkhead was rotten, given that the chain was primarily a big ball of rust and the rode was a sopping mess and Akupara had not been in the water in several years. Hmm doesn’t take a genius to figure this one out. How rotten it actually was, I wasn’t exactly sure. So my first attempt at using a grinder was not exactly successful. It’s not that it wasn’t getting the job done, but the dust that was thrown into the air resulted in everyone leaving the Captain to deal with this issue on his own. Not until several cat calls of something to do with “Breaking Bad” and all that. The Captain wasn’t impressed.

Needless to say, this did not last long. I would have had to have gotten the rest of the Breaking Bad attire in order to make it threw this one, and I had forgotten my safety glasses, so all in all it was a failed attempt.

So a quick trip to Lowe’s this morning and a new power tool was on board. And regardless of what the Admiral tells you, I did not make her sit down and watch online reviews of oscillating multi tools. Ok maybe 1.

Dewalt won the review challenge by the way.

Dewalt won the review challenge by the way.

On several of our last boats I have done things the hard way. I have made do with inadequate or improper tools and eventually was able to get whatever task was at hand finished. I must be getting old because my patience have simply run out and in this case anyway, this tool is worth its weight in gold! I have already thought of about a dozen different ways I will be able to use this in Akupara’s refit!

Back to the bulkhead. The new tool cut through the fiberglass with a lot of ease and best of all with a lot of precision. There is a learning curve to the variable speed and the stock blades that came with it are crap as I burned out 2 of them, but I will purchase new blades next time around.

Of course like any good boat project, you must twist, contort, climb inside of, pry beat, kick, pull, push, swear, sweat, give up, cry, yell, give in, try again, and then once you have completed the entire ritual, sometimes you win.

So, after all of that, Akupara is now one bulkhead short. In the process of all of this, it became clearly evident that either I am somewhat superhuman in strength, or the bulkhead was for the most part toast.

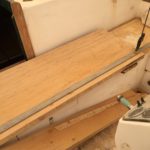

A couple of coats of paint later and all is good. Next week comes the fun part. Grinding, cutting, swearing, staining, fiberglasing etc etc as the new bulkhead goes in.

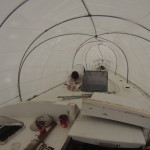

On another note, we have been discussing a lot of interior design ideas and the one thing we keep coming back to is installing dark corian counter tops. Since we had a can of old black paint kicking around, I decided to see what the whole dark countertop idea would look like so I painted the tops. Don’t worry, either way, the countertops were being replaced so not a big deal.

We kind of like the look. Of course it won’t be high gloss black, but you get the idea.