It is interesting that yesterday we loaded the truck at home and brought parts of Akupara back to Akupara as opposed to the other way around. I guess that means we are just past slack tide and the flow has begun to go in the other way!

It is a great feeling to be at this point and start seeing some results of all of our hard work. The process of gutting and cleaning was a long one and the biggest part is yet to come, the engine removal, but the tides have definitely turned!

Yesterday I put the finishing touches on the anchor locker by cutting the rubber mats I was talking about to fit and by installing the rode divider. I changed my mind about glassing the divider in as it would make any further work in there nearly impossible so I went with a gigantic screw to hold it in place. This means that when the time comes to wash out the locker, I can remove the divider and the mats and get it nice and clean!

I also managed to glass in the two holes in the cabin that had previously contained instruments. Last weekend we cut the marine plywood plugs and yesterday I took the grinder, bevelled the edges, and glassed them in with 6 layers of cloth and some structural filler in the epoxy. Next time down I will need to grind them flush and fill with fairing filler and epoxy so that there is no trace of them when we paint.

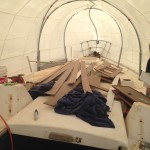

While I was doing all of this, Andrea and Paige were sanding their hearts out. All of the ceiling slats were sanded on the visible side with the orbiting sander and any paint from the back side that dripped was removed by hand. They spent the majority of the day doing this and their efforts were clearly visible based on the amount of sawdust on the two of them.

Strange thing though, my random orbit sander started to act up around hour number 4. It started making funny noises and also had a weird smell of burning brushes. The admiral swore that she had been emptying it and that she had not been hogging it down hard but nevertheless it just wasn’t working well anymore.

Sabotage I say! And if this is the kind of thing that is going to happen on a regular basis, ie I am tired so I will break the tool, I need to revisit the overall budget for this project and increase the tool allowance! Thankfully there is a Lowe’s hardware store about 10 minutes away so the any more of this nonsense will result in new tools 😉

It is starting to get nice in the Pacific North West and under the shrinkwrap it is even warmer! So we broke our own rule of not having beer on the boat until we launched and enjoyed our first ice cold beer on Akupara amidst all of the chaos!

As the ladies were finishing up the sanding of the v berth pieces, I was installing some insulation. Insulation? Yes insulation! There are 3 reasons we are adding insulation as we proceed through this rebuild. 1) As we plan to liveaboard, any heat we can retain will be advantageous as we both hate being cold. 2) When we finally get to warmer climates, the insulation should do the opposite and help to keep the belly of the beast a little cooler. And 3) I have heard a rumour that adding this silver bubble foil insulation actually increases your radar return to other vessels. I am not completely sold on this as I have no direct proof, but anything that increases our radar signature and makes us more visible to oncoming ships in the fog, is a good thing in my mind!

By adding the insulation beneath the ceiling, I have left a 2″ air gap in between the hull and the ceiling. So, cored hull which is warmer than a non cored hull, 2″ dead air space, and reflective insulation beneath the ceiling, should keep us toasty warm and hopfully reduce any condensation buildup.

And after a long day of work on several different projects, we almost have the v berth back to a state of completion.